Products

Adjustment concepts of LARI drag harrows

11.02.2022

Adjustment concepts

It is February outside, which means that the new agricultural season will soon begin. LARI drag harrow will enter the field much earlier than other machines. It levels the field after autumn plowing, crushes clods of earth in the surface soil layer, which retains moisture and destroys weeds. And every competent agricultural worker should know the features of setting up and adjusting this machinery in order to start field work as quickly and efficiently as possible.

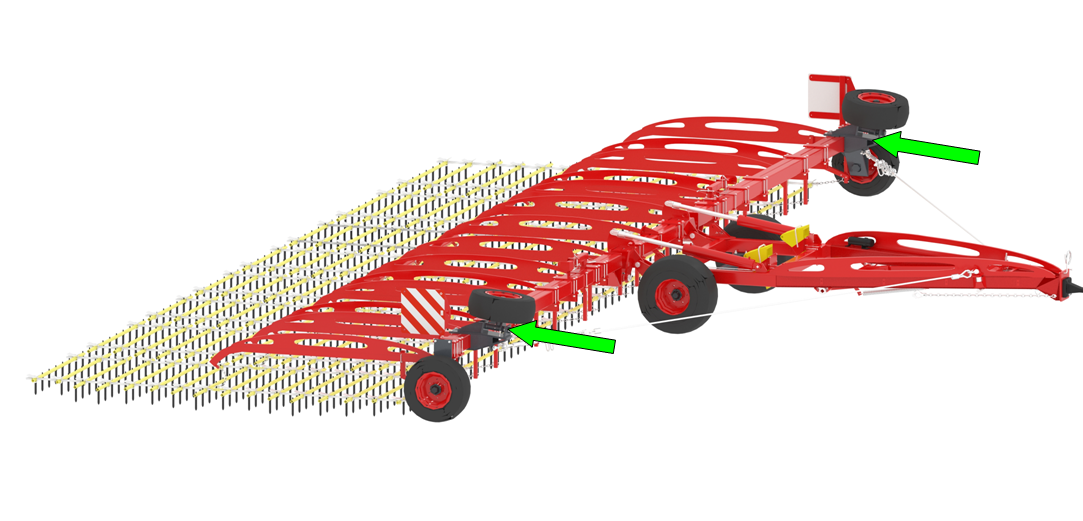

“As for the length of the bracing cables, it is adjusted with the help of screws with the machine wings unfolded. When the wings are perpendicular to the axis of the machine, the length of the cables changes until they are tighten. The position of the screw tie is fixed with two lock nuts,” the expert noted.

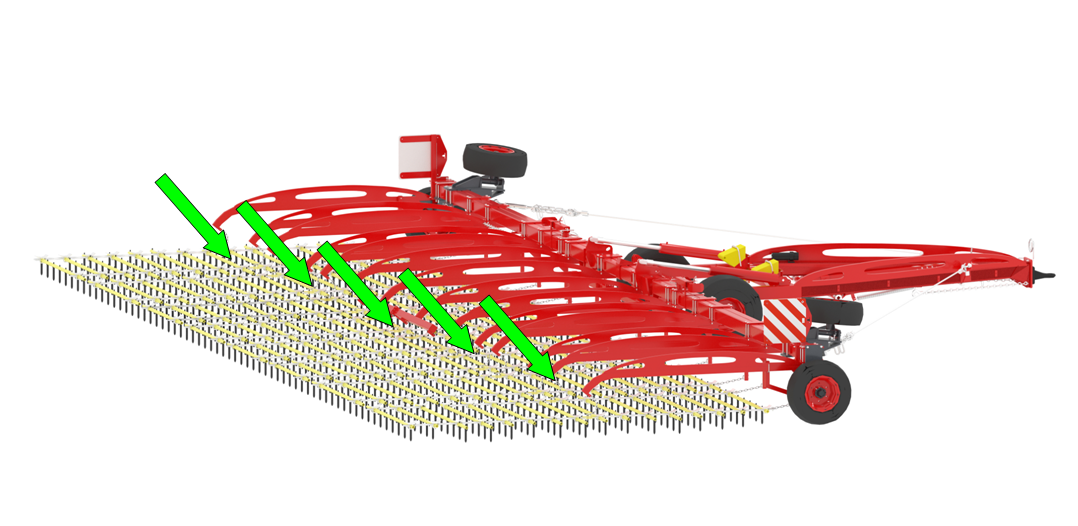

An important step is to adjust the teeth inclination angle to the surface to be machined, since the inclination angle determines the severity of the tools impact on the soil and is chosen by the decision of the agronomist of the farm.

“Here we have a two-position adjustment. It is performed by rearranging the drags (turning them by 180 °) and is determined by the bending angle of the wings of the adjusting plates, which are located on the transverse pipes of the drags. It should be noted that during the machine operation, the teeth of the drag harrow deviate to the angle that is determined by the inclination of the front plate wing towards the direction of the machine’s movement,” says Alexander.

By the way, LARI has the most wear-resistant teeth in the market. They are made of special spring steel with zone heat treatment. Due to this, their working face has a high hardness (55…60 HRC).

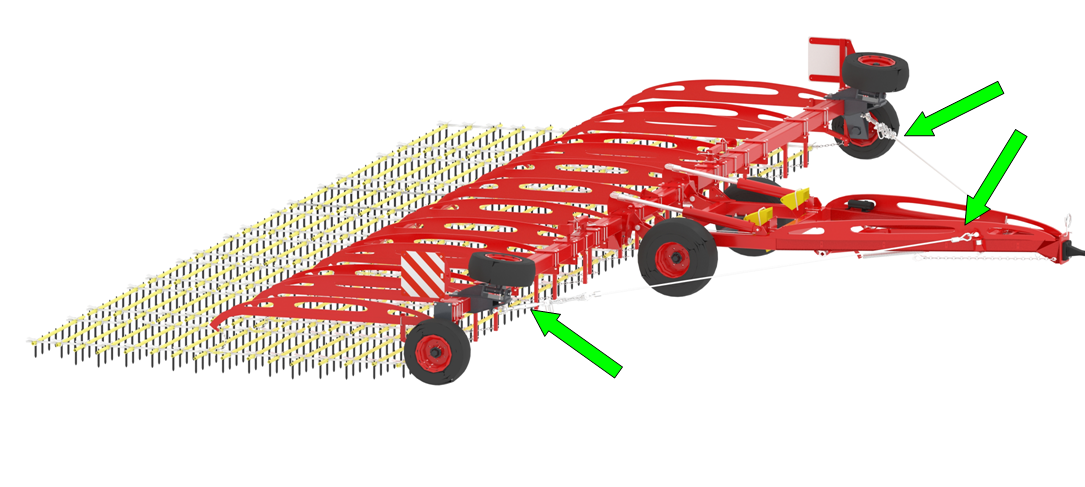

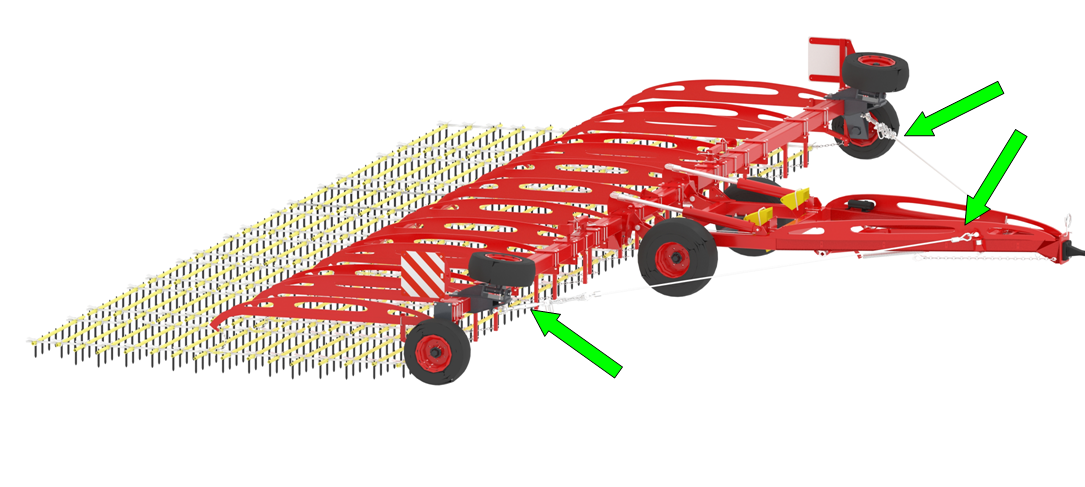

For quick and easy transfer of the machine to working condition and folding into the transport position, it is necessary to correctly adjust the toe-in angle of the transport wheels.

It is adjusted with the help of stop bolts in the area of the wheel hub. The position of these bolts is fixed with locknuts. By the way, for convenience, the adjustment sequence is shown on the wheel stand. You won't be able to do wrong!

And finally, it should be noted that the LOZOVA MACHINERY assortment includes drag harrows with a working width of 7, 12, 15, 18 and 21 m. LARI is effectively used both in spring and autumn. It is also successfully used for fallow fields.

Wish you successful tillage, good weather and a rich harvest!

Money works!

By tradition, the head of the service department, Alexander Shepel, shares tips on setting up the tillage machines of LOZOVA MACHINERY.

The main steps for adjusting the LARI drag harrow are the following:

- adjustment of the actuation moment of the trapezoid lock;

- length adjustment of the stretching cables of the machine wings;

- two-position adjustment of the teeth inclination angle to the machined surface;

- adjustment of the toe-in angle of the transport wheels.

The actuation moment of the trapezoid lock is adjusted by changing the length of the lock drive cable. Draft adjustment is carried out with metal clamps on the cable, and fine adjustment is carried out using a ring with a threaded section and nuts on this section. The cable length is adjusted in such a way that when the brackets of the tool sections are raised at an angle of 45 °, the lock latch is set in motion and opens the lock.

“As for the length of the bracing cables, it is adjusted with the help of screws with the machine wings unfolded. When the wings are perpendicular to the axis of the machine, the length of the cables changes until they are tighten. The position of the screw tie is fixed with two lock nuts,” the expert noted.

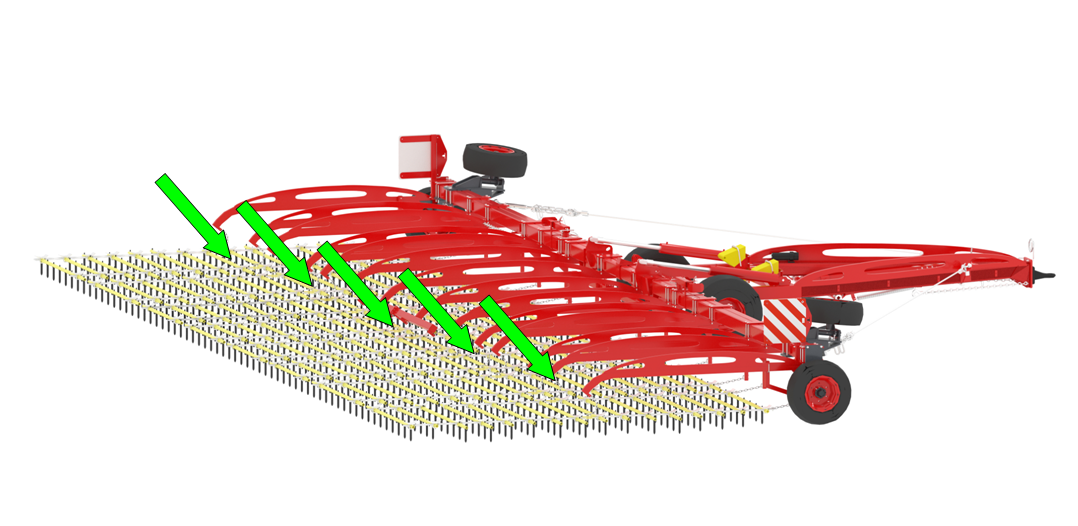

An important step is to adjust the teeth inclination angle to the surface to be machined, since the inclination angle determines the severity of the tools impact on the soil and is chosen by the decision of the agronomist of the farm.

“Here we have a two-position adjustment. It is performed by rearranging the drags (turning them by 180 °) and is determined by the bending angle of the wings of the adjusting plates, which are located on the transverse pipes of the drags. It should be noted that during the machine operation, the teeth of the drag harrow deviate to the angle that is determined by the inclination of the front plate wing towards the direction of the machine’s movement,” says Alexander.

By the way, LARI has the most wear-resistant teeth in the market. They are made of special spring steel with zone heat treatment. Due to this, their working face has a high hardness (55…60 HRC).

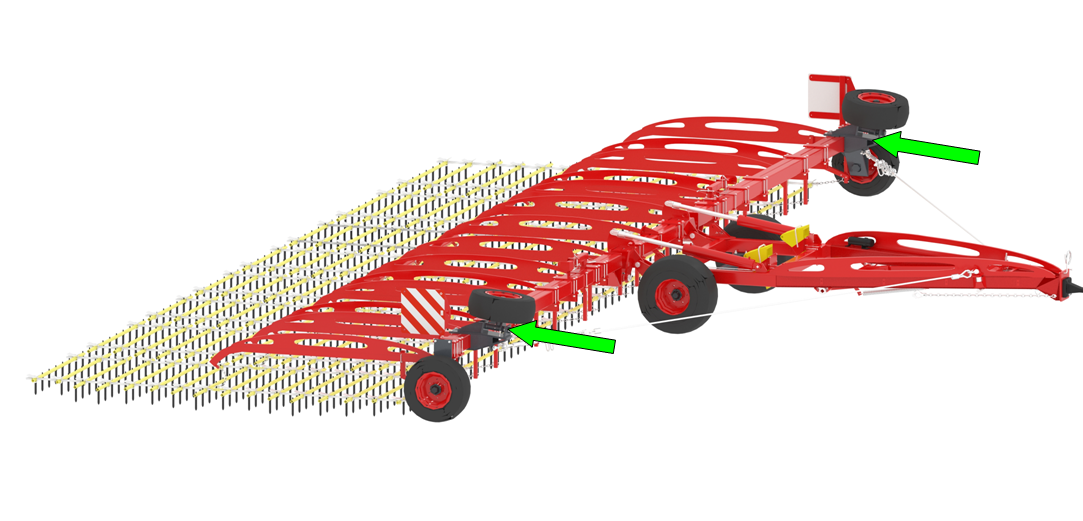

For quick and easy transfer of the machine to working condition and folding into the transport position, it is necessary to correctly adjust the toe-in angle of the transport wheels.

It is adjusted with the help of stop bolts in the area of the wheel hub. The position of these bolts is fixed with locknuts. By the way, for convenience, the adjustment sequence is shown on the wheel stand. You won't be able to do wrong!

And finally, it should be noted that the LOZOVA MACHINERY assortment includes drag harrows with a working width of 7, 12, 15, 18 and 21 m. LARI is effectively used both in spring and autumn. It is also successfully used for fallow fields.

Wish you successful tillage, good weather and a rich harvest!

Money works!

LOZOVA MACHINERY

HARP

HARP

UPEC Industrial Group

UPEC Industrial Group