LOZOVA MACHINERY SUBSOILERS - OVERVIEW AND FEEDBACK

OVERVIEW AND FEEDBACK

This year, the LOZOVA MACHINERY subsoilers - FRANK and GULDEN - are celebrating their 5th anniversary.

They entered the market together, just after the extremely dry fall of 2015. The land was simply "petrified" and many farmers were concerned with the problem of plowing and deep tillage.

Vladimir Artemenko, chief engineer of the “Garant” farm says:

“We had a plot of barley stubble, which we did not manage to plow. The plows simply broke on it. As a result, the field was forsaken. In the spring, we used a subsoiler FRANC, to a depth of 25 cm and sowed sunflower. Frank really helped us a lot. "

What are these subsoilers? What should they be used for? What do the farmers say about them? Let's figure it out together.

AGROTECHNICAL EFFECT - 3-4 YEARS!

“Our subsoilers are designed for the main deep cultivation of the soil and destruction of the plow sole to improve the soil water-air condition. After our subsoiler’s work, the soil's ability to absorb and pass water from the surface improves," chief designer Alexei Grinenko says.

The machines cultivate the soil at great depths, without turning the layer, leaving on the surface from 30 to 60% of plant residues. It solves the problem of soil erosion, preserving the organic composition and, therefore, guaranteeing its long-term fertility.

So functional tests of the Institute named by L. Pogorely showed that the subsoilers GULDEN and FRANC increase the water permeability of the soil by 75%. It significantly improves the water-air condition of the soil and its yield.

“The soil really breathes. It has been tested on our own land,” Yuri Sergienko, director of Belovodsk-Agro praised the work of the subsoiler.

SAVES TIME AND MONEY

One of the most important advantages when using LOZOVA MACHINERY subsoilers is resource saving due to a well thought-out design, technological combination of several operations and the ability to use the machine during all periods of field work.

“We took the subsoiler just so that it would not stand idle in the spring and summer. We try to take multifunctional machines,” Yuri Stepanov from Odessa region says. “And we did not regret it. We do use two seasons in a year, which I think is very beneficial. And, of course, it is convenient for us".

"ZERO MAINTENANCE"

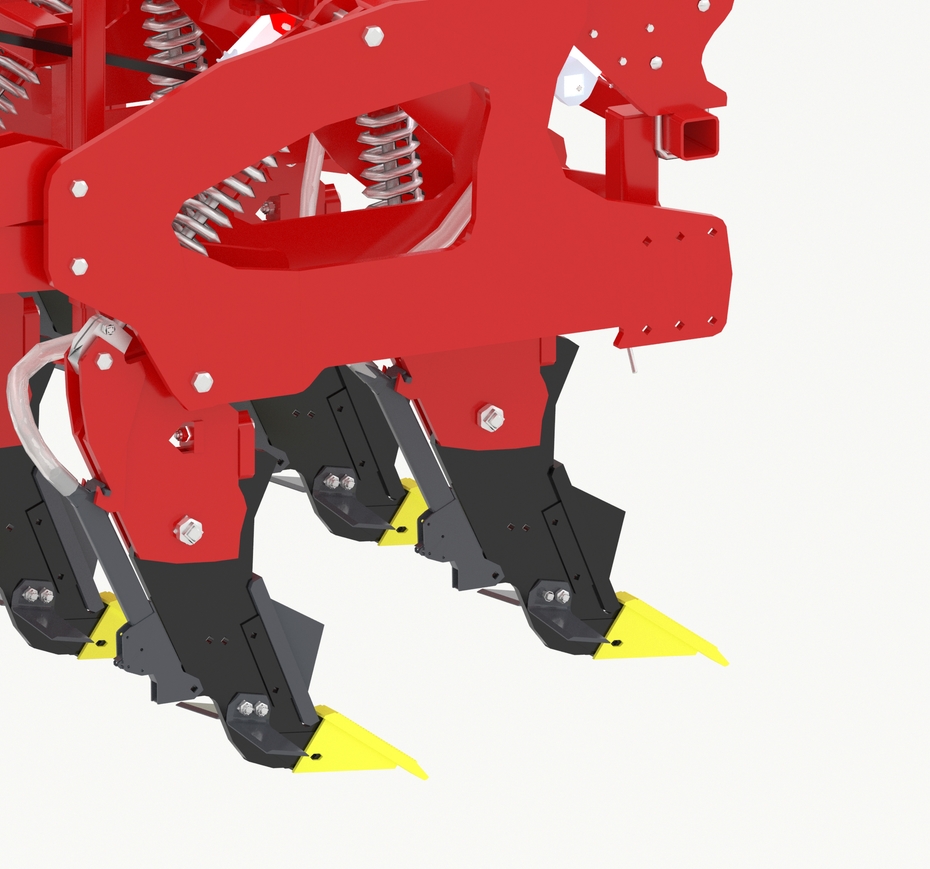

As in all LOZOVA MACHINERY equipment, the principle of " ZERO MAINTENANCE " is implemented in subsoilers. Bearings and units do not require lubrication. The balancer is fitted with bimetallic plain bearings. The crowfoot roller is self-cleaning. And the working bodies are equipped with wear-resistant tips HARD-SHELL. The frame and other elements of the unit are "indestructible". All this practically excludes maintenance of subsoilers during the whole season.

“I am one of the first buyers of GULDEN,” Leonid Artemenko, Zori agricultural firm, says. “I use it constantly, and on the most clogged lands - well, it is exactly where I need it. What can I say - I have not yet welded or repaired the machine. I changed the tips, yes, well, and this is understandable for so many years! And everything else is fine."

HARD-SHELL EXTRA WELL-RESISTANT TIPS

FRANK and GULDEN working bodies are equipped with chisels with carbide tips, trade mark HARD-SHELL.

These bodies have a longer service life, which significantly reduces operating costs and ensures a consistent working depth. The front-point is quickly changeable, which, combined with a long service life, does not require time for replacement and maintenance. At the same time, the very design of the working bodies facilitates tillage, reduces soil resistance and requires less tractive effort.

“Do you understand that FRANK requires a tractor of less power, and what kind of savings does this give “per circle”?” Alexander Stolbovoy, director of the Kolos farm enterprise, says. “Thousands and tens of thousands only on fuel, this is obvious. And how about increasing the resource of the tractor? And how about reducing the cost of oil, maintenance, and repairs in the end? That's where the hidden profit are!”

Tests and examinations of independent institutes, as well as field work in pilot farms have shown that the service life of working bodies with HARD-SHELL carbide tips is increased by 3-3.5(!) times, in comparison to standard tips.

SPRING PROTECTION

Subsoilers come standard with shear bolts to protect the tines and frame, but newer models also use spring protection. In the event of a collision with obstacles, the spring mechanism protects the tine from wear, which is especially important in difficult rocky soils. This protection increases the comfort and ease of use of the implement, improves the quality of tillage, minimizes downtime and reduces maintenance costs.

FERTILIZER APPLICATION SYSTEM

For the last couple of years, at the request of farmers, LOZOVA MACHINERY subsoilers can be equipped with a system for precise application of granular fertilizers during tillage (at levels of 150 and 250 mm). This system has received a lot of positive reviews for its convenience and efficiency. It significantly saves fertilizers, increases yields and preserves the natural soil balance.

The use of LOZOVA MACHINERY FRANK and GULDEN subsoilers preserves the organic composition of the soil, improves the water-air condition and soil fertility.