Rules for adjusting the GULDEN subsoiler

Rules for adjusting

Both in summer and in autumn, one of the most relevant implements for a farmer is LOZOVA MACHINERY subsoiler, which break down the plough sole at a depth of 45 cm, while keeping the topography of the field. Deep loosening improves the structure of the soil, contributes to the best aeration of the soil and its saturation with moisture. This, in turn, leads to the accumulation and preservation of more water in the soil and creates the prerequisites for the development of microorganisms and bacteria necessary for the growth of the cultivated plants. The company's range of subsoilers is represented by FRANC and GULDEN units.

Today, we will talk about the rules for adjusting the unit for continuous tillage using subsoiling technology: the GULDEN subsoiler with a working width of 4 m. “For your information, loosening with this implement is carried out, at the choice of the farmer, in one or two levels of the ploughed layer with varying degrees of soil pulverization. This effect is achieved by a combination of two types of working bodies on the unit - subsoiler tines in front and tines with plough shares behind them. The delta-shaped frame of the unit is able to withstand heavy loads caused by the resistance of the soil when working on two levels,” says Oleksandr.

There are four types of required implement adjustments:

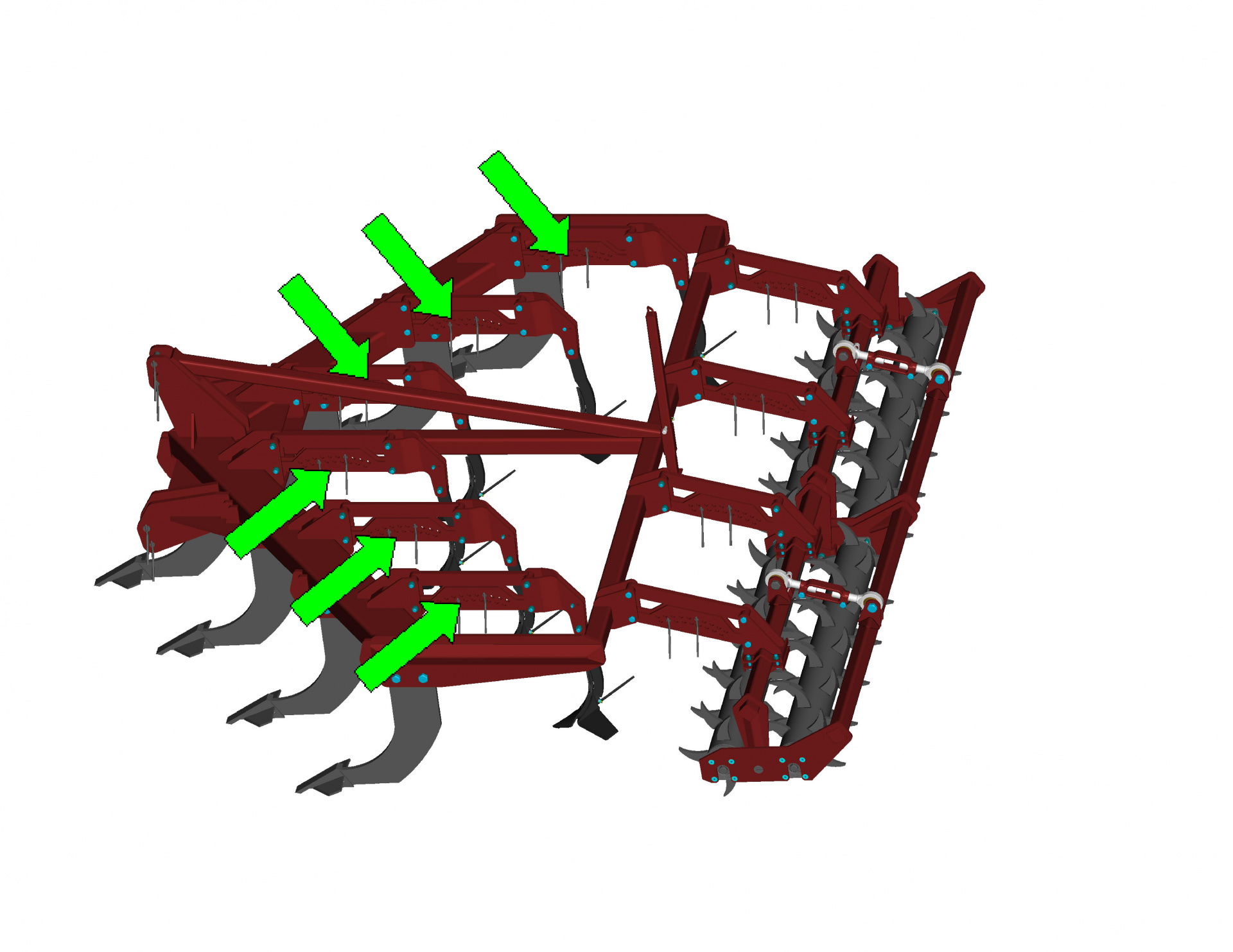

- adjustment of the horizontal position of the subsoiler frame;

- depth of tillage;

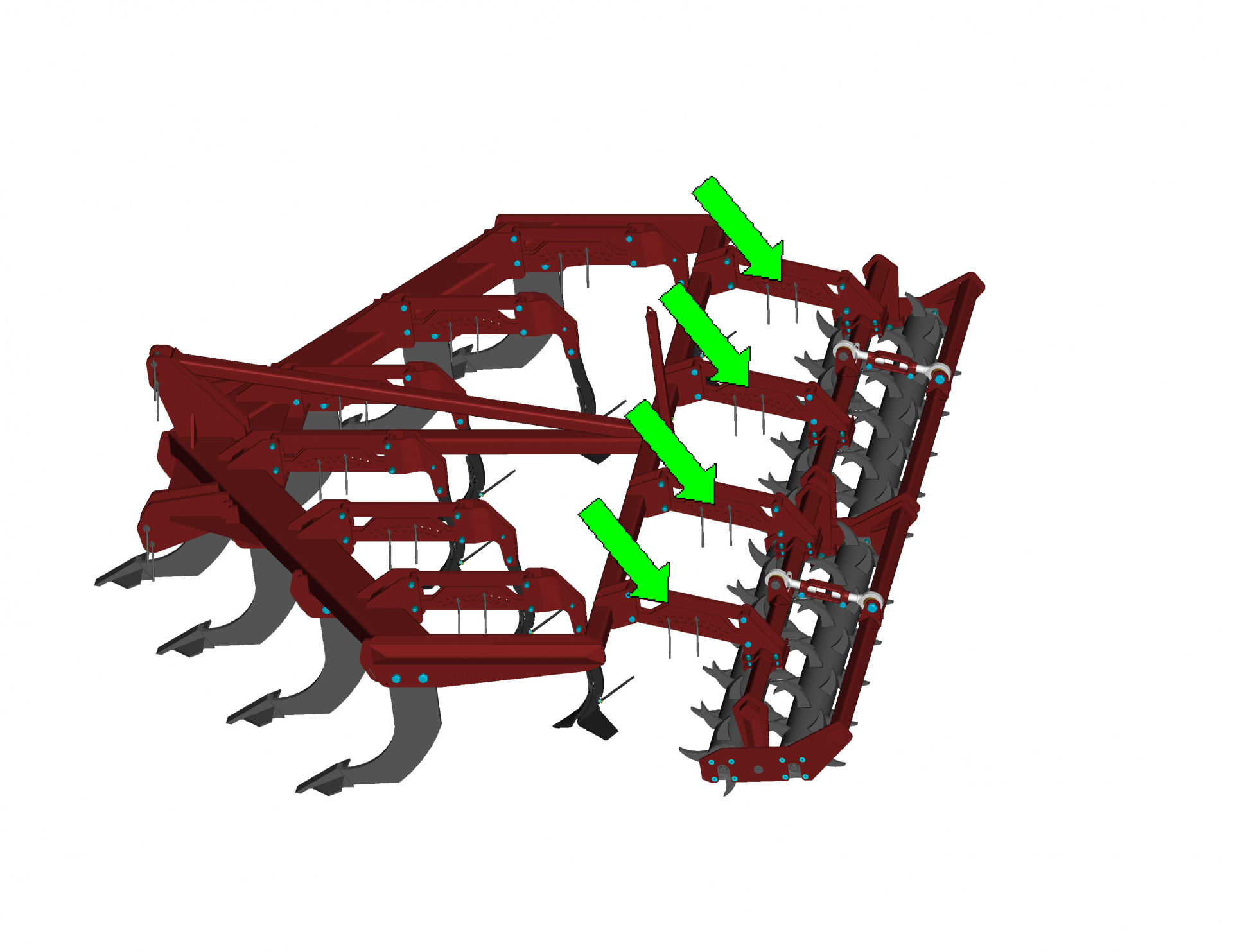

- position of the plough shares;

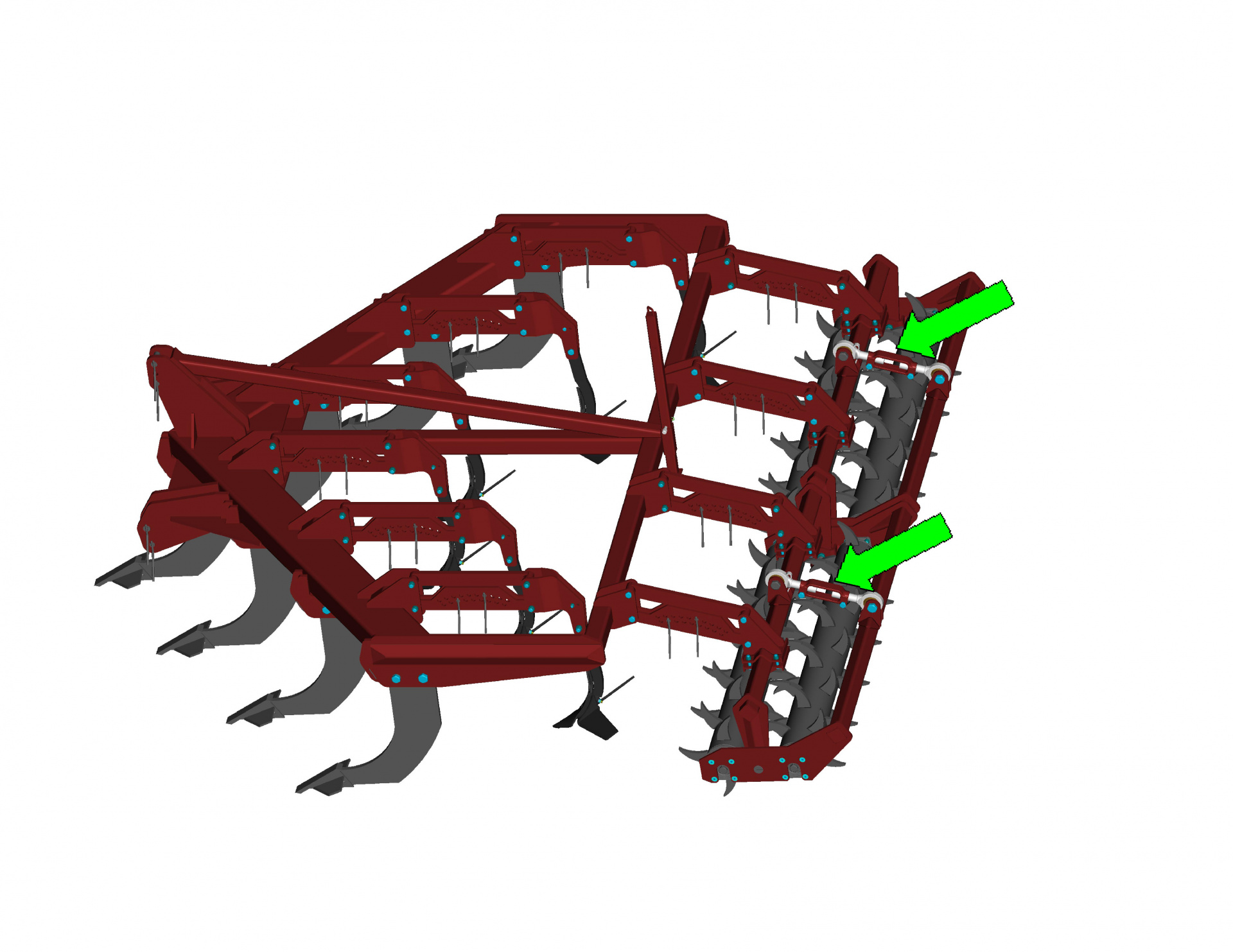

- position of the rollers relative to each other.

The horizontal position of the frame guarantees a uniform tillage depth across the working width of the unit. This position of the frame and the specified depth of soil cultivation are achieved by mutual adjustment of the position of the tractor's hydraulic linkage and the position of the levelling rollers. The rollers serve as a support for the rear of the unit during its operation and limit the depth of the working bodies.

“The plough shares, installed after the chisels, allow additional loosening of the soil in the upper soil layer and achieve a finer fraction of clods on the surface. This reduces the rate of evaporation of moisture reserves and optimizes the soil texture of the topsoil,” adds the expert.

Both the position of the rollers and the working depth with the plough shares are adjusted discretely mechanically by the mutual position of the spacers: the lower one (perforated) and lower one (with a stop) using the locking axes.

Oleksandr also warns that when working on soils with high moisture content, as well as with a large content of crop residues on the surface, in order to prevent "shovelling", it is not recommended to use plough shares. In such cases, they are exposed to the extreme upper position and become passive.

The relative position of the rollers is adjusted with struts. With an increase in the length of the strut, the rear roller falls below the front roller, and vice versa.

“We recommend adjusting the relative position of the rollers so that the rear roller axis is 20-25 mm below the front roller axis. This will reduce the chance of soil clogging up between the rollers. At the end of the adjustment, it is necessary to fix the position of the strut screws with the tie bolts,” advised Oleksandr Shepel.

The use of deep loosening in the technology of growing agricultural crops allows you to quickly restore soil fertility and achieve the highest yields. And GULDEN is one of the best equipment for this.

To be continued…

LOZOVA MACHINERY

HARP

HARP

UPEC Industrial Group

UPEC Industrial Group